“Hayley and STW have been a great asset to our company and have assisted us with their knowledge and professionalism.”

Reliable NDT services

Reliable NDT services

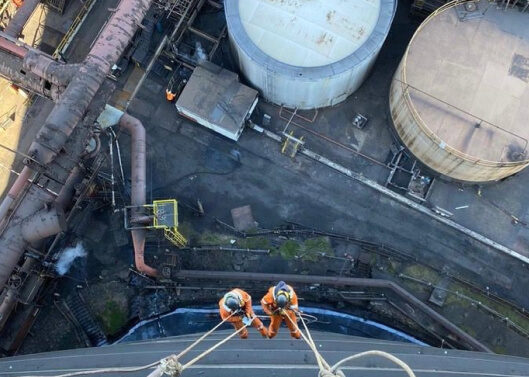

Here at S.T & W Inspections, we provide Non-Destructive Testing (NDT), welder qualifications, weld procedures, RWC services, and inspection consultancy to the highest standard. We carry out a wide variety of Non-Destructive Testing techniques to ensure your components are acceptable to the given industry-specific acceptance standards. Our team has more than 10 years of experience within the industry, combining our varied skillsets and knowledge to create a service that highly benefits our clients and gives them confidence in the quality of their products. Our commitment to the industry comes from working in multiple sectors. These sectors demand the highest level of knowledge and skills required for the inspection of safety critical components. Our clients’ satisfaction is extremely important to us, and we always find a way to fulfil urgent, critical, or specialist inspection requirements. To enquire about our services, call us on 01795 432 634.

“Hayley and STW have been a great asset to our company and have assisted us with their knowledge and professionalism.”

“Great service, friendly, helpful and accommodating.”

“ST&W Inspections are a very reliable supplier of ours. They are quick to support us at with any inspections that we require sometimes on a short turnaround. This includes completing paperwork that we require to give to our clients and also if an inspection is required on site, they are always reliable to be able to meet our demands. Also, their knowledge of the industry is massive support to us when we require information when we might not have the answers.“

“It is genuinely a pleasure doing business with you and I look forward to continuing the relationship and using your services“

Non-Destructive Testing is a wide group of analysis techniques used in engineering, science, and technology sectors to evaluate the properties of a material, component, or system without causing damage. NDT is implemented in many industries, including:

In maintaining critical infrastructure and assets, the importance of NDT cannot and should not be over-emphasised. With proper implementation of NDT testing programmes, our clients are able to confidently supply their products to the end user, knowing they have been inspected thoroughly.

We offer a wide range of Non-Destructive Testing techniques, ensuring that no matter your project or your requirements, we have something that will be suitable for you. Our range of services includes:

During Ultrasonic Inspections, the equipment emits beams of ultrasonic sound waves at varying frequencies. This enables the NDT technician to determine the internal quality of the component under inspection. This technique is used on a multitude of different components, most commonly on butt welds in pipe or plate, bolts, shafts and as a tool to carry out thickness checks. It can be used on components which can’t be traditionally measured.

Visual Inspections are carried out by an expert eye. They assess the surface of the weld and the parent material, confirming that there are no visible surface discontinuities and ensuring the weld has been made to the correct dimensions as specified on project drawings. If you do not have an in-house Visual Inspection team, our technicians can carry out Visual Inspections on your behalf. This technique is used during our welder qualifications and approval process.

The method of Magnetic Particle Inspection can be applied in several ways. A common method uses a white contrast paint, and a solution containing iron filings. By manipulating a magnetic field using an AC yoke over the item, the iron filings are drawn to damaged areas, alerting our technicians to faults. Another method uses a fluorescent ink and UV lamp to inspect components which cannot be painted, such as bearings or hard-to-clean smaller items.

Liquid Penetrant Inspection (LPI) applies a dye or penetrant liquid to the item for inspection after rigorous cleaning, ensuring no debris contaminates the test. After the solution is carefully removed, the surface is sprayed with a developer, drawing the liquid out of any surface discontinuities through capillary action. LPI does not require the material to be ferrous, therefore aluminium, stainless steel and other alloys can be tested. The various methods are:

Fluorescent and water washable LPI are typically used for larger batches of work.

Throughout the UK, District Heating pipelines are being rapidly installed – the welds used in the installation of these pipelines must be tested to ensure they are compliant with the relevant British Standards. Our bespoke NDT methodology allows us to test these thin wall pipelines without employing methods which may be more time consuming and expensive to our clients.

Phased Array Ultrasonic Testing uses an advanced transducer to send multiple beam frequencies through the material of the test component. The inspection’s theory is similar to traditional Ultrasonic Inspection. However, it uses a wider range of frequencies which gather information, creating a detailed image of the internal condition of the component being inspected.

Positive Material Identification (PMI) can be used to analyse any material’s chemical composition. This type of inspection is commonly used on metallic components but can be used on any material. PMI is often used on existing in-service components to identify the material before a repair can be carried out appropriately. A number of techniques can be used to carry out PMI – our experts will identify the most appropriate one for your component.

To find out more about how our weld testing services could benefit your company, contact us on 01795 432 634 or email info@standwinspections.co.uk. You could also fill out our contact form for a same-day response. We look forward to hearing from you.

We have the expertise within our team to be able to offer welder qualifications, renewing these every six months before the necessary retest in two to three years. Your business may also benefit from working with our sister company, S.T & W Laboratories, where we conduct Non Destructive Testing and Destructive Testing on components that cannot be completed onsite. Some of the Destructive Testing techniques we offer are:

An RWC (Responsible Welding Co-ordinator) is a member of our team who oversees all welding activities, including inspections. We can visit your business on a monthly or quarterly basis and will conduct a range of services to confirm your compliance with the correct British Standards. These include consulting on new weld procedures, welder qualifications, and performing internal audits on your behalf.

At S.T & W Inspections, our standard of work is unwaveringly high. We prioritise a seamless service for our clients, identifying exactly which service your project requires before carrying it out efficiently. When working with us, you can count on:

Our team holds innovation at the forefront of our services, ensuring that we can solve any problems that come up onsite or in our labs. Our innovative approach has also allowed us to develop a method of NDT for district heating. We will continue to advance the standard of our services and maintain our compliance with BS EN ISO 9001 Quality management systems.

Our knowledge of the industry is extensive, and we work closely every day with the relevant British Standards that are required in the welding industry. Our expertise can be used to ensure you are compliant with these standards, allowing you to be confident in the performance of your components.

Within our services, we offer techniques for different projects. We will be able to easily identify which of our services you require and will then carry them out effectively. If you need more than one service, we are capable of doing this and can also conduct offsite testing with our sister company S.T & W Laboratories.

To witness our inspections in action and see how they benefit our clients, take a look at our past projects. You could also take our clients’ testimonials into account when considering our services.

If you’re in need of our NDT services, don’t wait any longer. Get in touch with us on 01795 432 634 or email info@standwinspections.co.uk to get started.